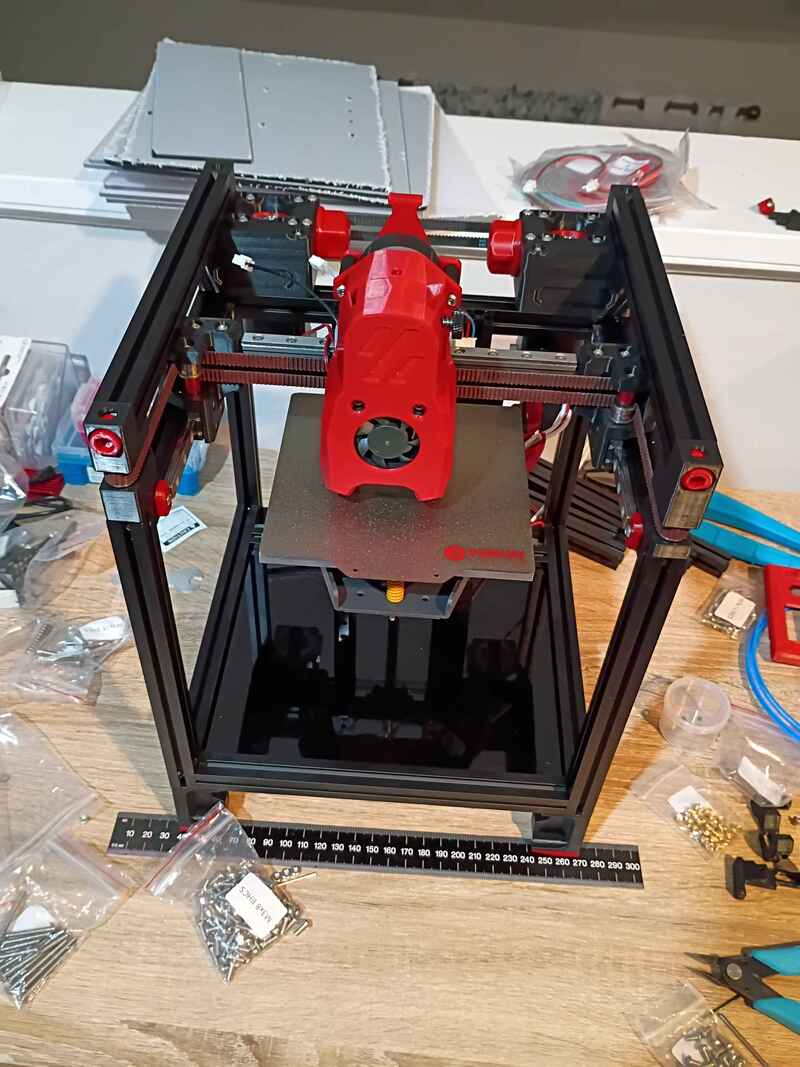

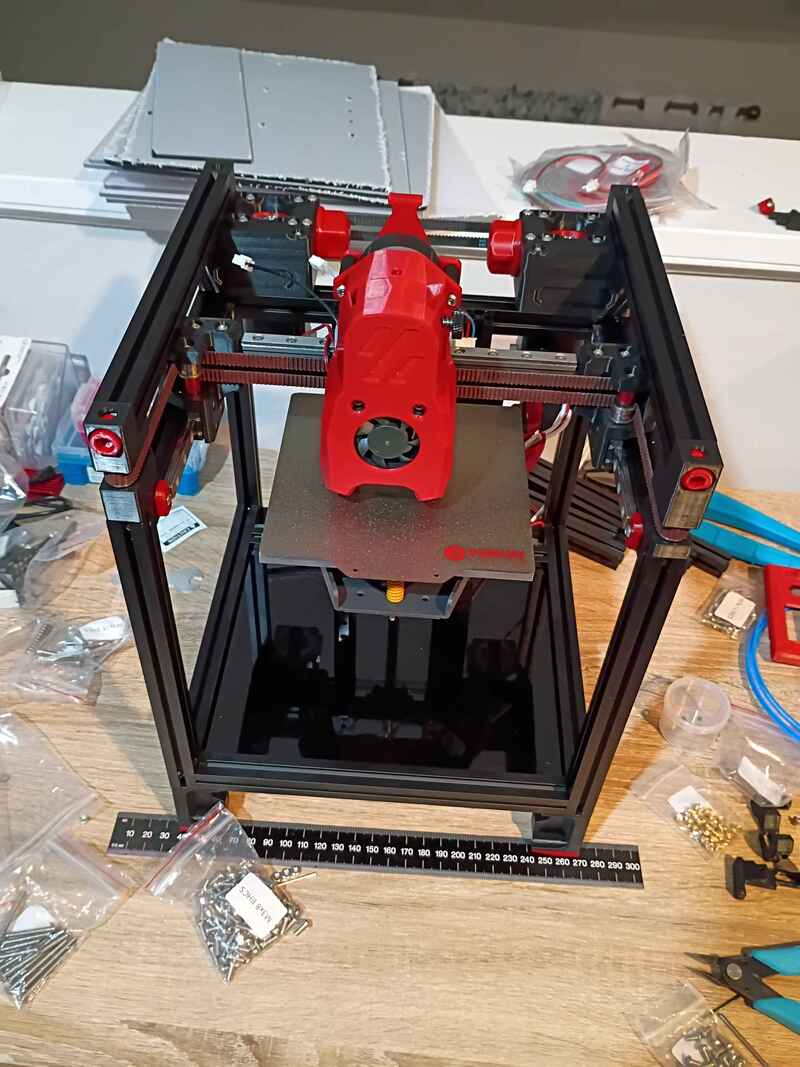

Continued to work on the Voron 0.2r1 kit. Completed most of the frame, motion system, and toolhead. Probably only 1 more day.

Started kit build of Voron 0.2r1.

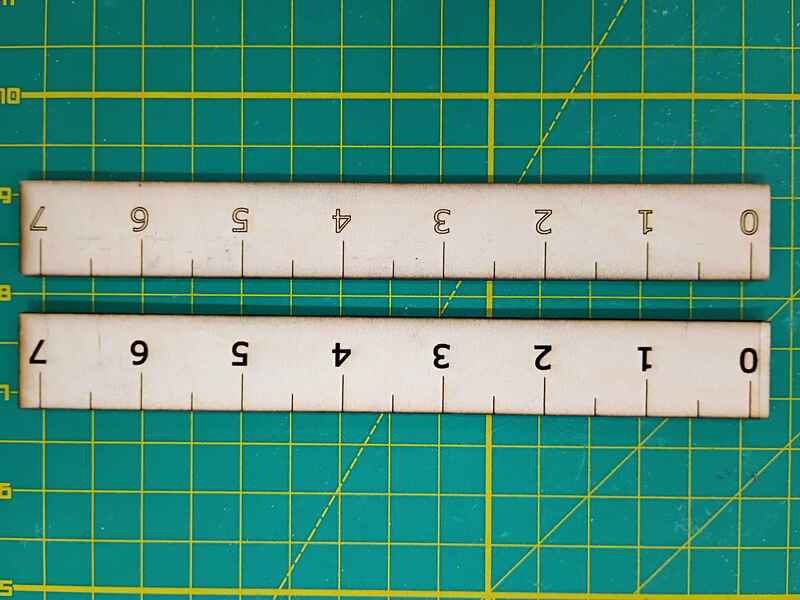

Laser cut some 03010-001 rulers.

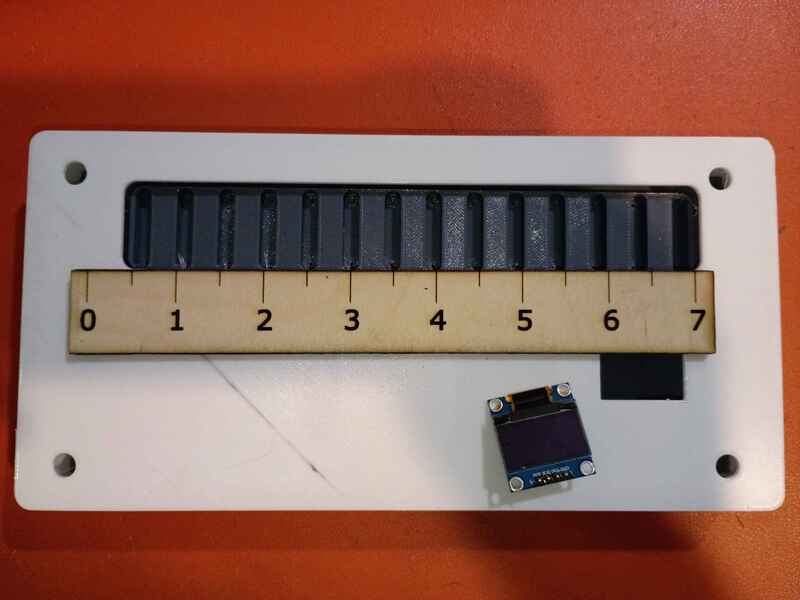

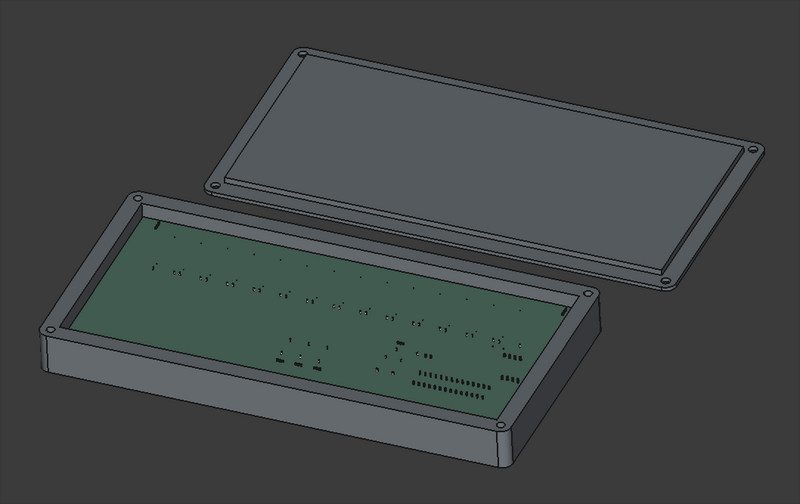

Tested box layout. May need to reprint the white body piece with the OLED cutout slightly lower.

Attached rubber feet to bottom.

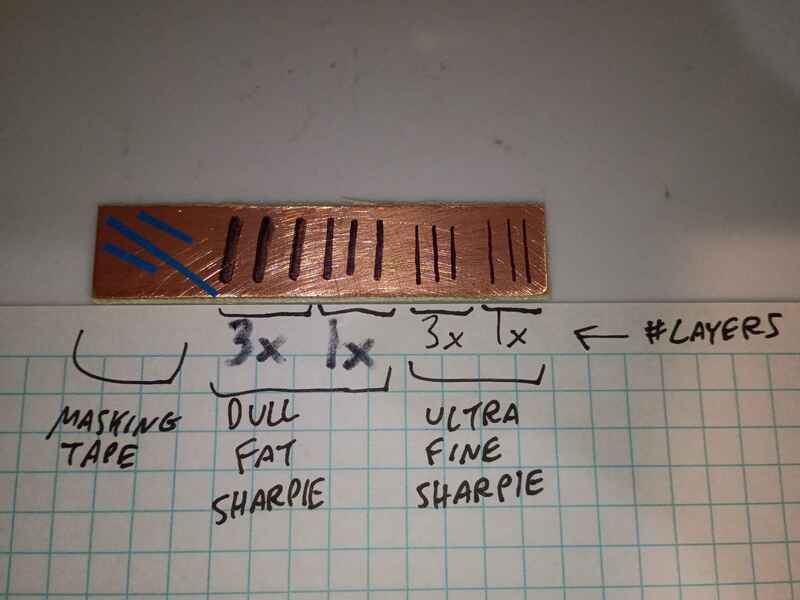

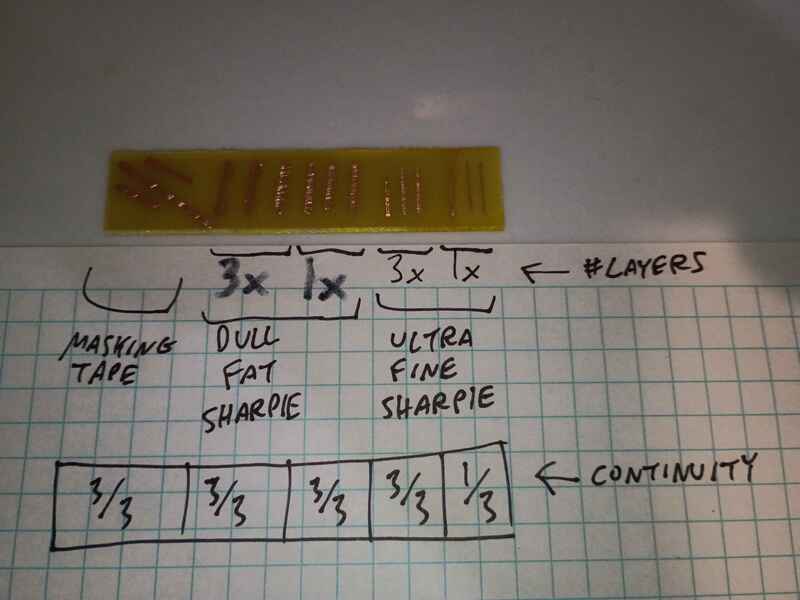

Tested various Ferric Chloride etch-resist options on a scrap piece of copper clad.

The finest and best solution is multiple coats/layers of the Ultra Fine Sharpie, or masking tape for large rectangular areas.

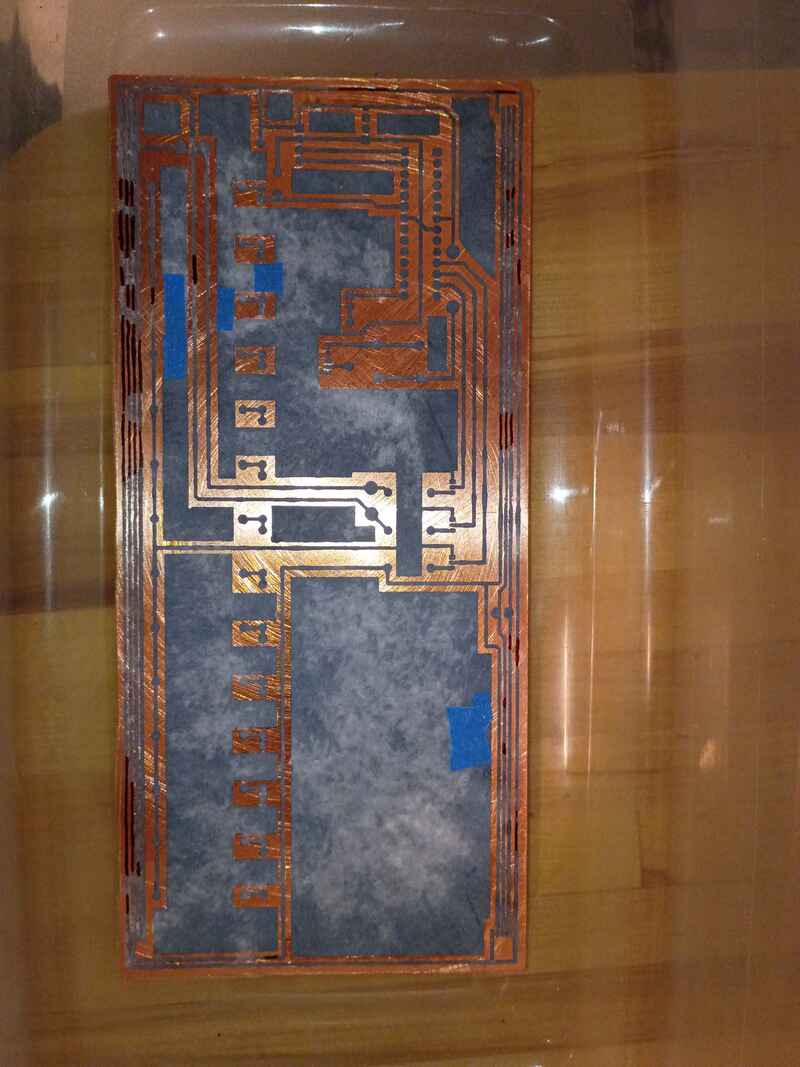

Used these solutions to repair minor issues in the toner-transferred copper mask.

Etched away the copper to reveal the traces.

Toner-transferred the copper trace mask on the copper clad board. It actually turned out decently for the size and relative complexity. The edges peeled off a bit, but that always happens for me; I will redraw those areas with Sharpie or masking tape. I also scraped off the lingering bits of paper with a knife. For future reference, I used the iron on max heat, let the board cool briefly before setting it in the water, and let it sit in the water for ~20 minutes before rubbing off most of the paper backing, and 20 more minutes before rubbing off any remaining paper residue.

Implemented "!editjournal" command in Mary-Bot to edit an existing journal entry. Date, project & author values are preserved, but text content and uploaded images are replaced completely. Intended to make it easy to fix small grammatical errors or replace pictures. The syntax is: "!editjournal 0094 Revised text content goes here." In fact, this journal entry was created and revised using this command.

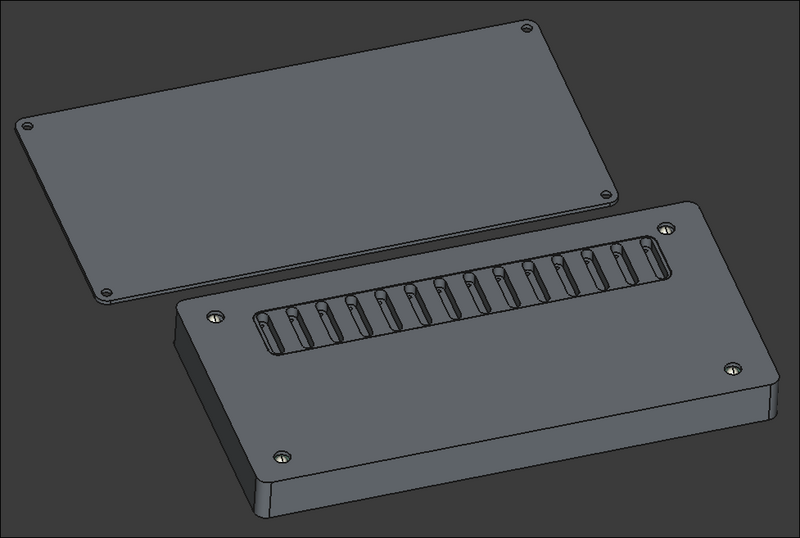

Successfully printed the box assembly from PETG. A little bit of warping on the large flat cover piece, though the screws should hold that in place, and a bit of discoloration streak on the top of the main box component, so I may need to sand/paint or cover with a sticker. Everything fits together well.

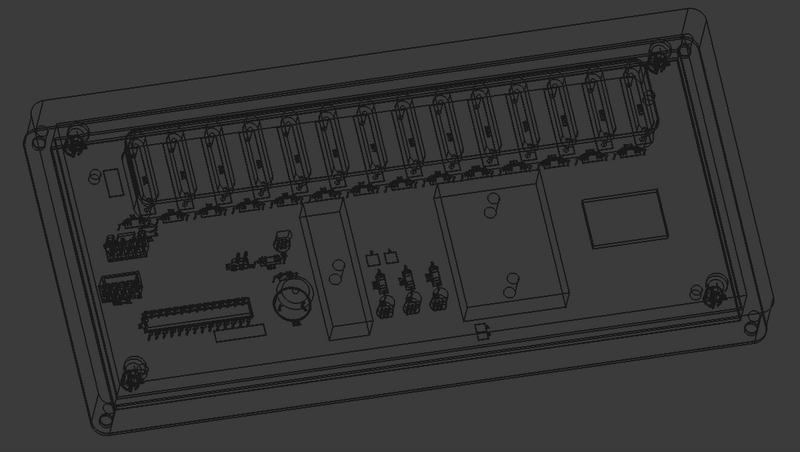

Completed design for a prototype box assembly that should support all the components and the rubber feet I already sourced. Since the part is quite large, it will need to be printed on the machine at work. I will try that tomorrow. I might need to iterate on the main support body at least once to get the depth correct.

Designed a 3-piece 3D-printed assembly for the project. One component to support the reed switches on the PCB, one box to mount the PCB assembly, and a lid. I still need to add a hole in the top face for the OLED screen. Everything is removably mounted with M3 screws.

Looking into possibly pivoting away from laser-cut plywood box to a 2-piece 3D-printed box. It would be more robust, reproducible, and suitable for this container, though it will be roughly 230mm wide, which is approaching the maximum for the Prusa MK3S that I will print it on, which may pose problems.

Finalized design of top and front/back of manipulative box. Still considering options for the bottom that are easy to remove for access to repair and replace components.