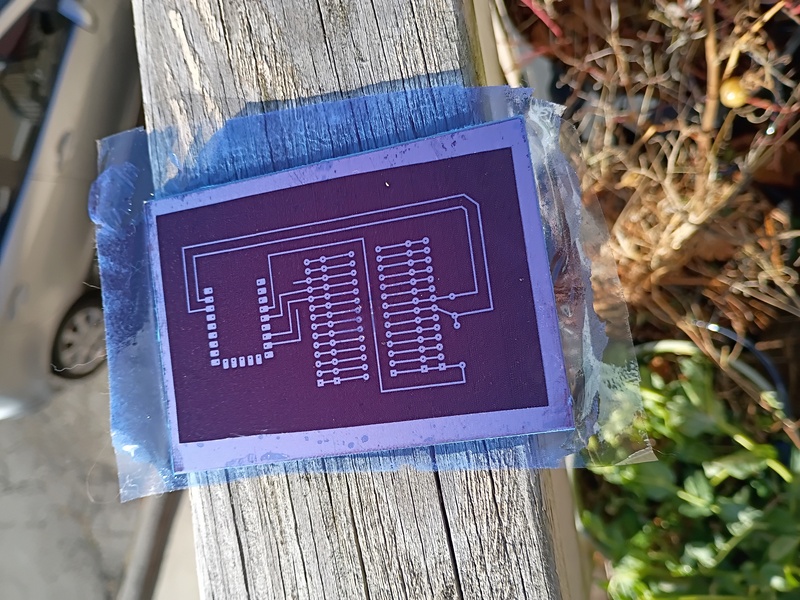

I didn't have a reliable source of UV, so I used the New England winter sun...

...which overexposed the photoresist after 10 and even only 5 minutes. Also I had bubbles in the film because I applied it with a clothes iron, whereas a laminator would have done a far better job. In any case, these two attempts failed.

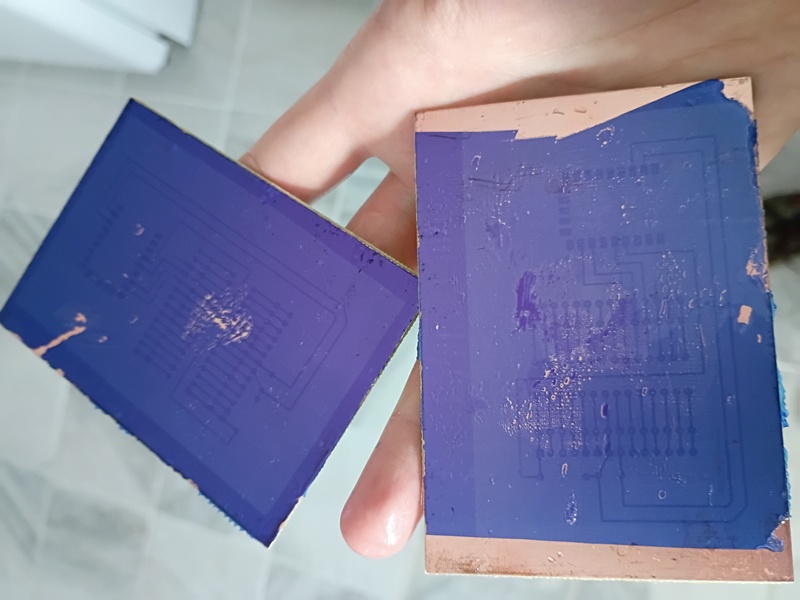

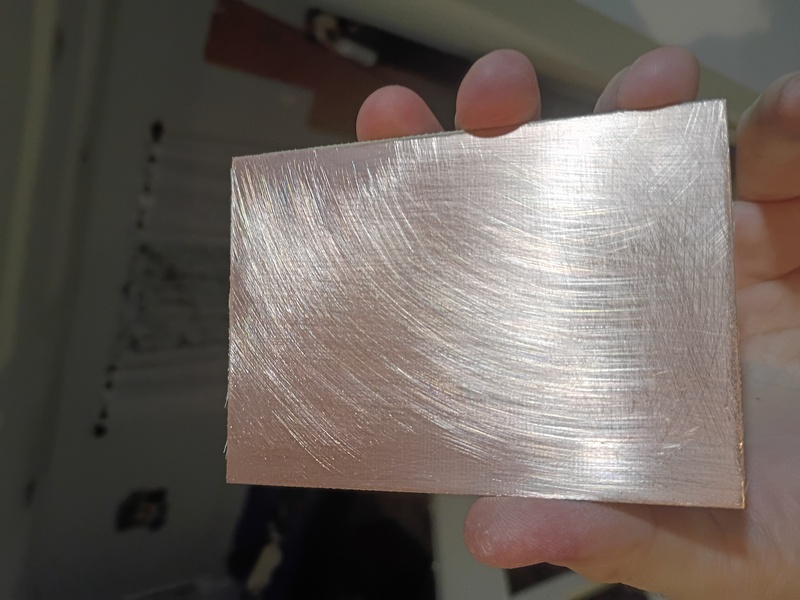

So I tried the toner-transfer method. I did a much better job of cleaning and scuffing the copper-clad board using 240-grit sandpaper and acetone.

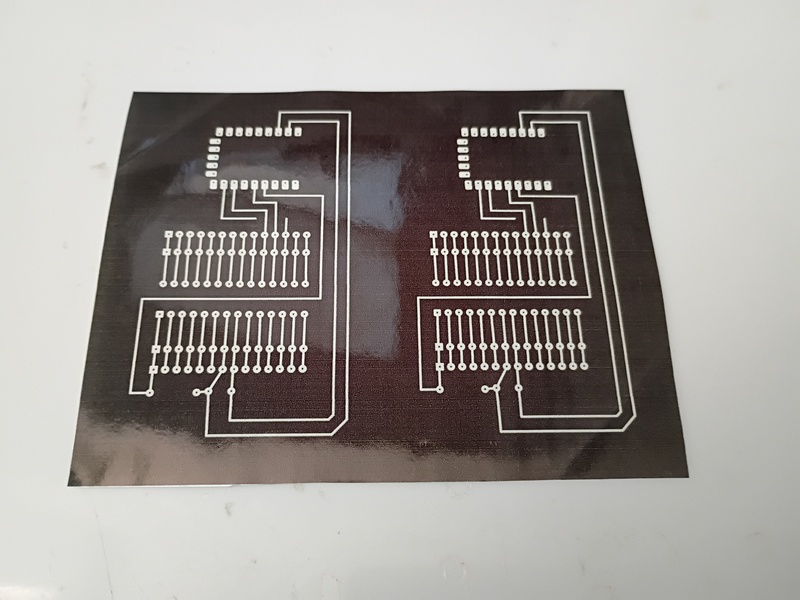

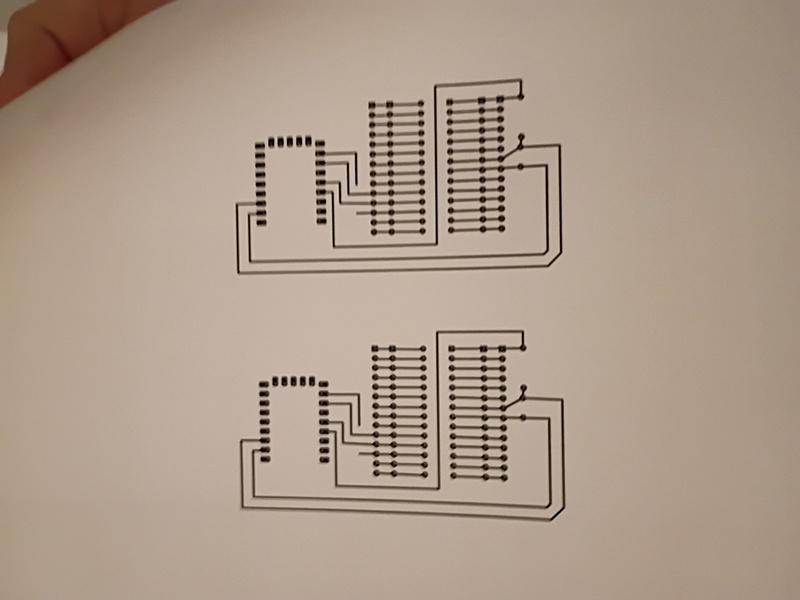

I printed a non-negated (and unfortunately mirrored, a mistake) plot on glossy paper using a laser toner printer.

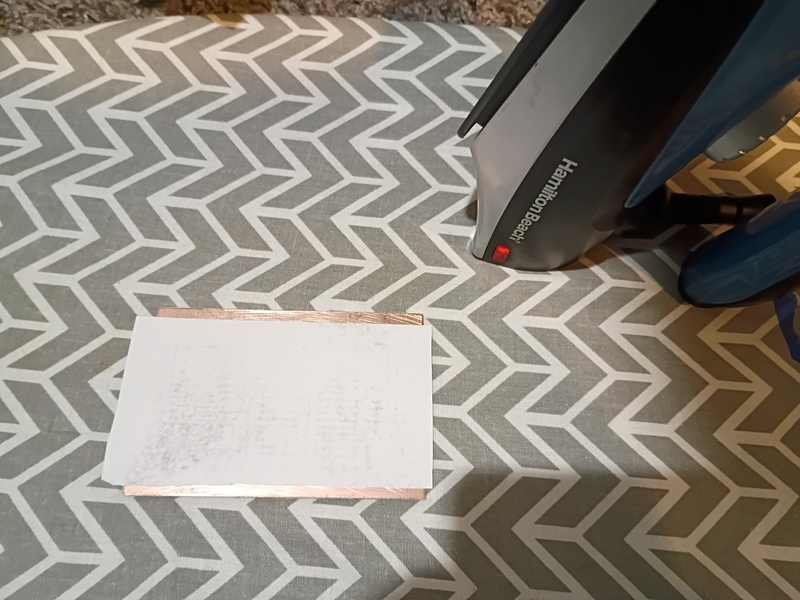

I ironed the paper onto the copper-clad board,

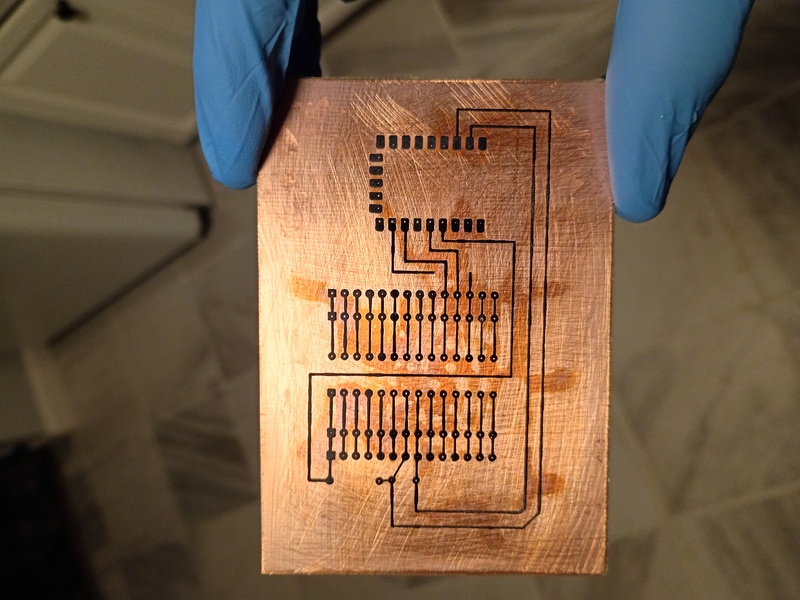

...and dissolved off the paper over 30 minutes in some warm water. You have to get everything off, even the white paper haze that might find itself between pins and traces that will otherwise prevent the etchant. Noticed I failed to do this on the right, where the RP2040-zero mounts.

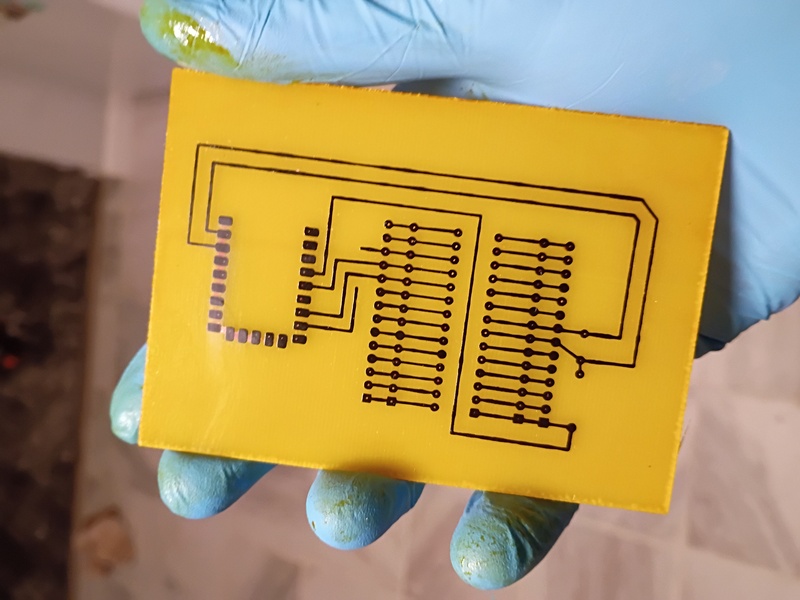

Then I set the board in Ferric Chloride and gently agitated it for 10-15 minutes outside. If I had made most of the board the ground plane, it would have gone a lot faster because less copper would have needed to dissolve away.

It turned out pretty well, but notice there was still some copper between the pads on the top of the board.

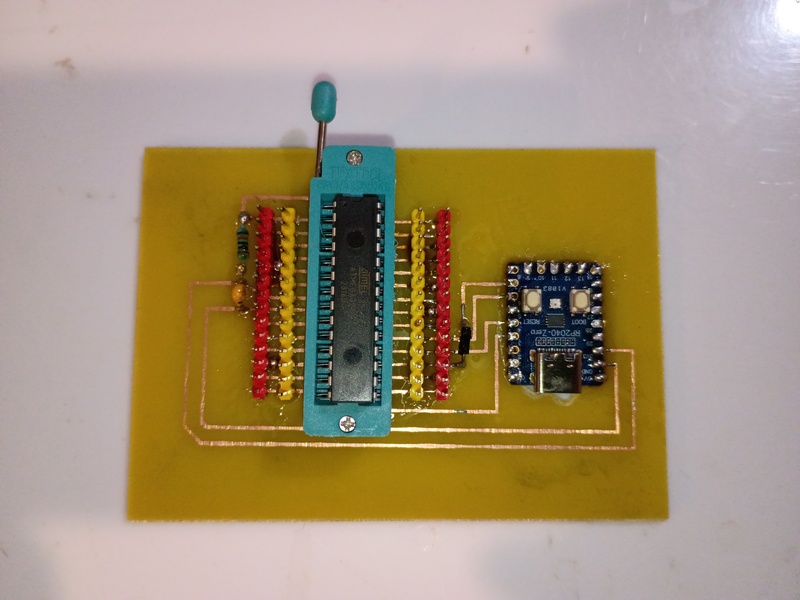

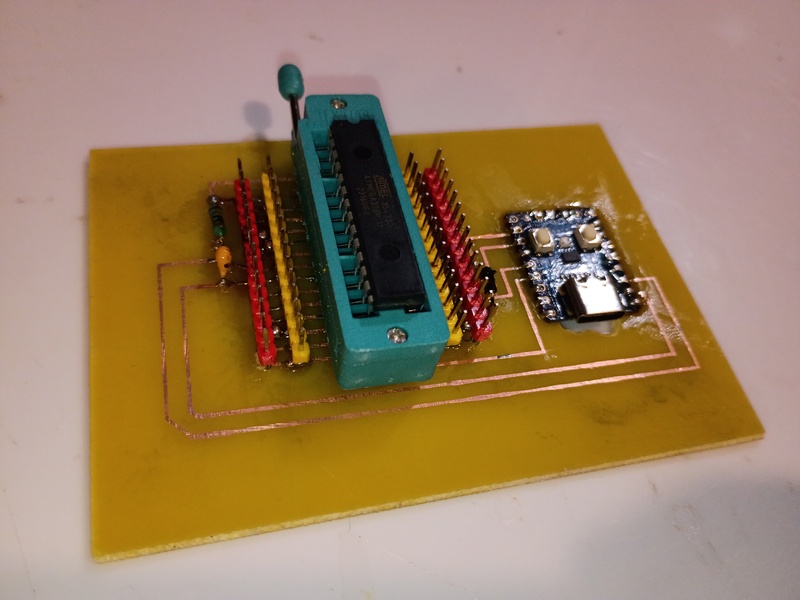

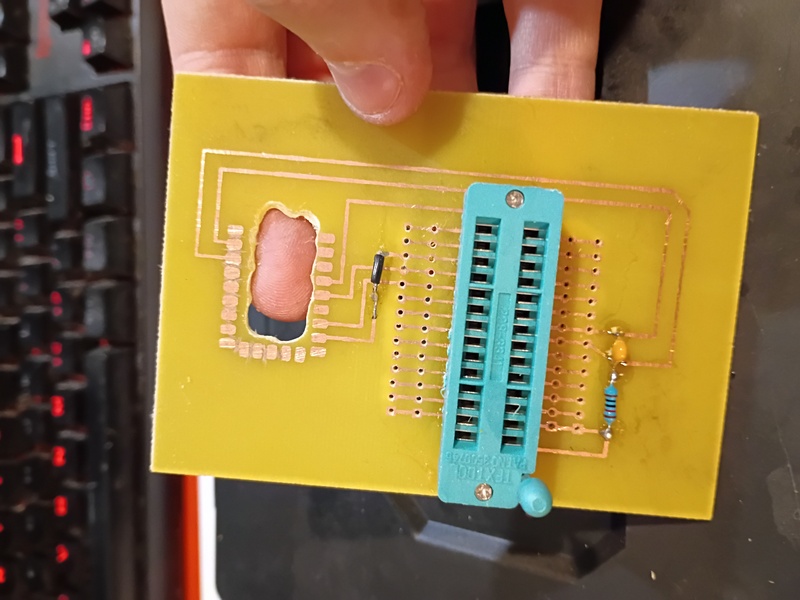

So I wiped the remaining toner off with acetone and popped some holes in using a very small 0.8mm endmill. In retrospect I should have made the copper pads larger, because I drilled out most of the copper even with my smallest endmill. I also drilled out a hole for the underside of the rp2040-zero board, which although it has castellated edges, cannot be set flat on a board without cutting away the board beneath it. Then I began soldering components. Again, in hindsight, my traces should have been on the opposite side of the board as my components, because they were extremely challenging to solder because the pads were directly beneath. In the future, traces should be on the background copper face if the components will be mounted on the top, and that would not have required that I even mirror the board plot in the first place. I could have also toner-transferred some nice-looking component labels and even a part number if I had set the traces on the opposite side as the components. Either way, this investigation was a learning experience, so I don't mind the soldering challenge and all the other added complexity.

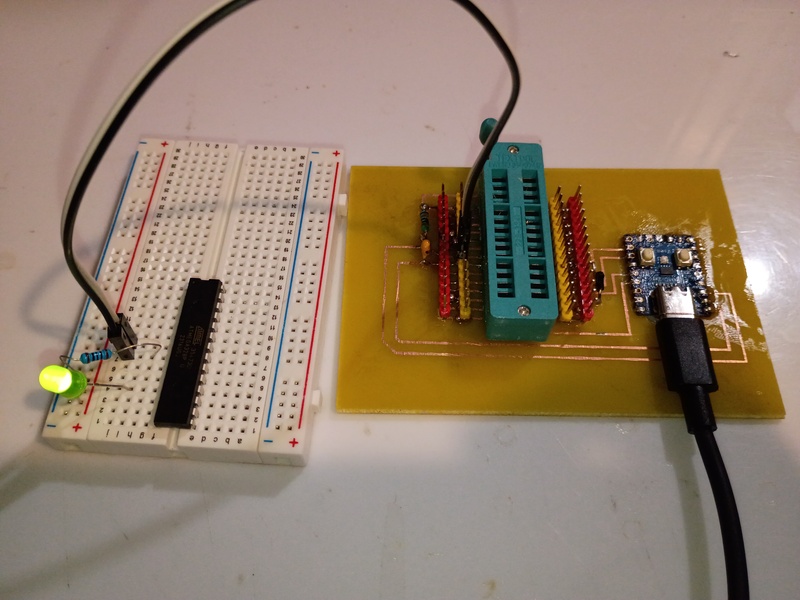

The photos below show the final product which actually works well as an Atmega328P programmer; I tested several blink programs. The rows of header pins also almost make this into an Arduino-like devboard, though it lacks any external oscillator or other peripherals. I did have to shave down the bottom of my USB-C cable so it could come in flush. A lot about this whole project could be improved significantly, but I had a lot of fun with it. This investigation was a massive success, and we did barely manage to complete it on schedule.